The art of engineering

When an engineering thesis project hit a snag, a turn to the arts campus revealed a solution.

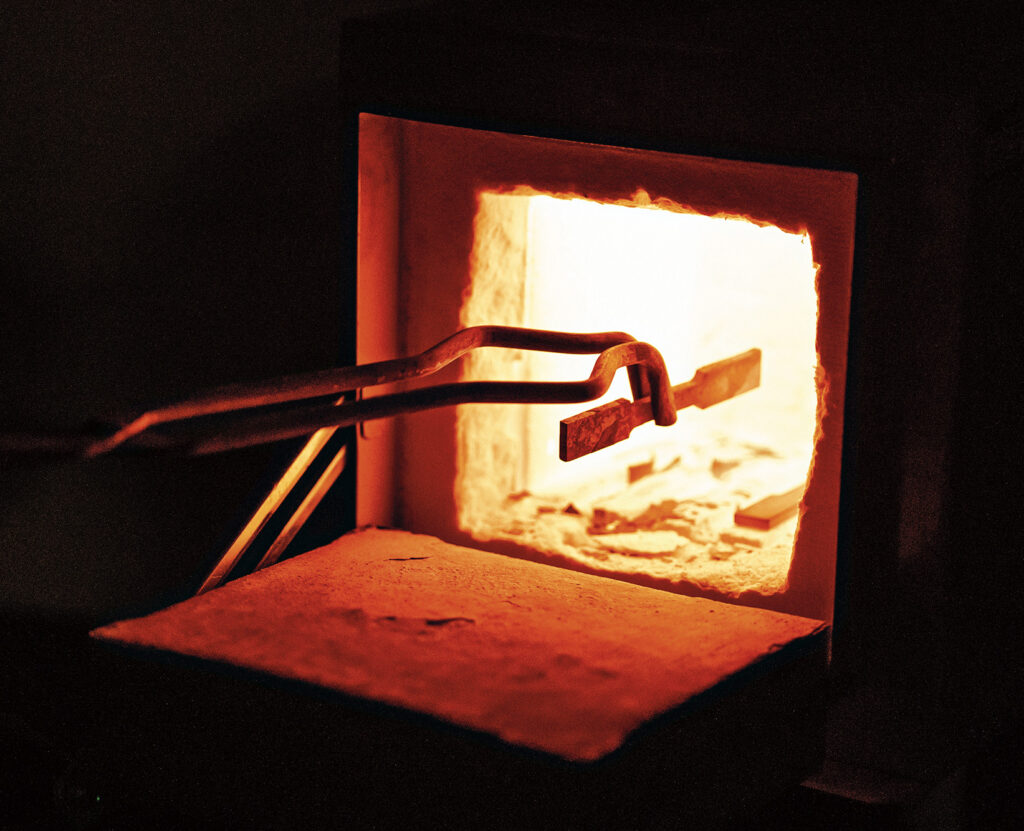

Steel is annealed in the furnace on the second floor of Acopian before it is quenched in water, a process that makes 3D-printed metal more pliable after it is fired.

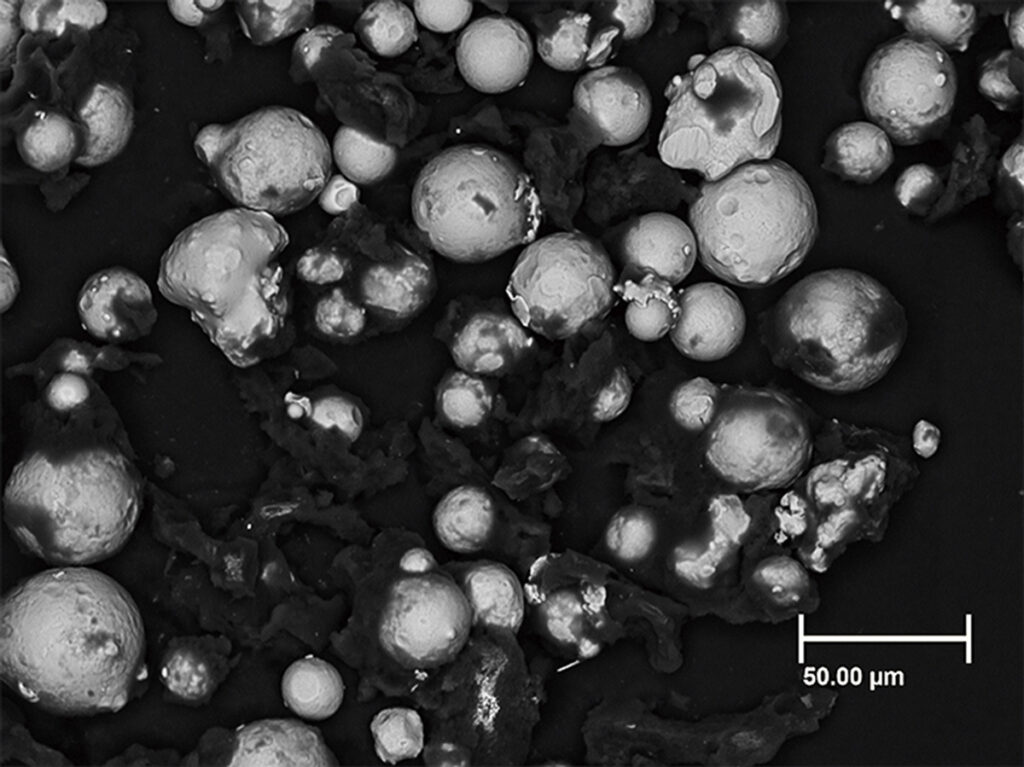

Photography by Matt Smith; (Particles) Courtesy of Charles Mann

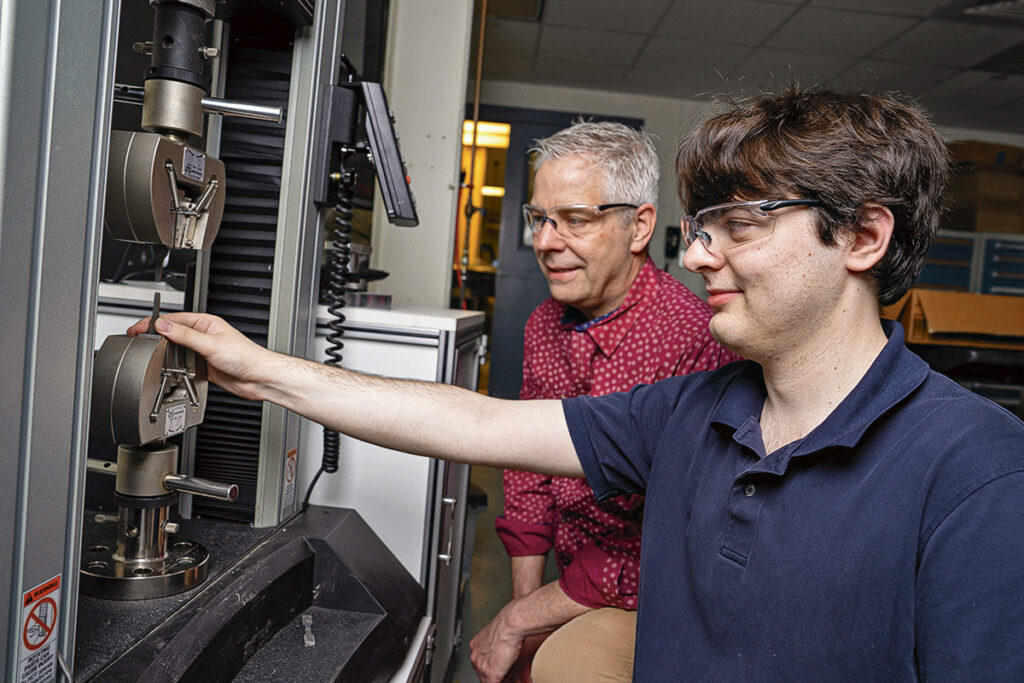

Exploring Lafayette’s campus is natural for Charles Mann ’25. A mechanical engineering major with a physics minor, Mann can often be found using the scanning electron microscope in the Biology Department or viewing the stars as co-founder of Astronomy Club. But as he worked on his senior thesis project, he encountered an unexpected turn: specifically, one that led him to the arts campus.

Mann’s thesis focuses on developing a method for strengthening 3D-printed metal parts. The project relies on recently developed filament that combines plastic with powdered metal. The filament is similar to weed wacker string except that it contains a high percentage of powdered metal that is mixed into the plastic. However, a problem arose when Mann and his thesis adviser, Professor of Mechanical Engineering Scott Hummel, started planning how to “heat treat” the parts, a process that helps burn off the plastic and converts the final product into solid stainless steel. They needed a furnace capable of high temperatures, or least 2,000 degrees Fahrenheit, with significant venting infrastructure.

“We could have gone to an outside vendor,” Hummel says. “But it became costly and slow, and not the kind of thing we wanted to try. We needed it here, and we just could not figure it out. And all of a sudden, it became clear that the arts campus had just the thing.”

That thing, a standard-issue pottery kiln, was only a short walk away. Mann contacted Prof. Nestor Gil, associate professor in the Art Department, who referred him to Chris Nappo ’27. An engineering studies and studio art double major, Nappo is also the president of Lafayette Pottery Club, the group that operates and maintains the kiln.

“They’ve been great collaborators,” Mann says of Nappo and Gil. Nappo was able to work with Mann to operate the kiln at a higher temperature than is standard for pottery, making it a new experience for both of them.

“I think Charles reaching out to us was great, and I would definitely like to see more engineers and artists mixing with one another,” Nappo says. “I’ve always wanted to bridge this gap, and I love that professors at Lafayette give incredible opportunities and resources to students.” “I hadn’t actually been into any of the buildings on the arts campus [until now],” Mann says. “It’s a great environment to be in. There are other engineers down there, and it’s amazing to see the projects people come up with.”

Currently, 3D-printed metal parts have a variety of uses from the medical field to aerospace, allowing astronauts to produce replacement pieces during orbit or surgeons to create customized implants that conform to a patient’s body. However incredible, these parts are generally not as strong as wrought metals. Through this research, Mann is helping to bring the strength of filament-based 3D-printed components closer to those traditionally manufactured.

Nappo, meanwhile, is interested in product design, a field that consistently blends engineering and art—and an area that would benefit from the expanded use of 3D printing.

“We like products because they’re well-designed and they’re enjoyable,” Nappo says. “That’s the collaboration between the artist and the engineer. They are actually harmonious.”

While Mann is advancing the efforts of manufacturing, his project is also having an impact on the Art Department. Mann’s work has shown that a regular 3D printer, metal filament, and a kiln can create works of art through a much more accessible process.

“We’re doing steel, but if they wanted, the Art Department could use bronze, copper, glass, or any other kind of filament,” Mann says. “If they wanted to make a sculpture out of bronze, they don’t have to cast it out of liquid bronze. They can just 3D print it, stick it in the kiln for a couple hours, and then out comes this piece of bronze.”

For Mann and Nappo, who hadn’t met before this project, it all comes back to how a Lafayette education encourages interdisciplinary discovery.

“I know that exploring other mediums will inform my pottery making,” Nappo says. “Lots of the work I do at Lafayette challenges my creativity, my problem-solving ability, and the way I view art.”

“It’s a great Lafayette story,” Hummel says. “The Art Department was able to ‘re-fire’ our project. No pun intended.”